Comprehensive guide for a one stop Non-Destructive Testing solution

Unlock the full potential of your manufacturing process with advanced Non-Destructive Testing (NDT) solutions tailored for semi-finished tool metal components.

Understanding the Importance of Non-Destructive Testing for Semi-Finished Tools Production

Non-Destructive Testing (NDT) is a vital process in the manufacturing industry, especially for semi-finished tool metal components such as bars, tubes, wires, and billets. It enables the inspection and evaluation of materials and components without causing damage, ensuring they meet quality standards and are free from defects that could lead to failure in later use.

This approach provides manufacturers with an objective and reliable basis for both process control and final product evaluation. By leveraging state-of-the-art NDT solutions, manufacturers can detect and localize early-stage defects—such as microscopic cracks, inclusions, material inconsistencies, or surface irregularities—before they compromise performance or safety. NDT not only builds confidence in downstream production steps but also aligns manufacturers with stringent regulatory requirements, reduces recall risks, and supports a best-in-class reputation for end-to-end quality assurance.

In semi-finished tool production, NDT plays a crucial role in maintaining component integrity and reliability. Early defect detection minimizes costly rework, reduces downtime, enhances safety, and ensures product performance. Furthermore, NDT supports compliance with stringent industry standards and regulations, ensuring components are fit for their intended use.

This proactive approach safeguards downstream processes and fosters long-term customer trust by consistently delivering components that meet or exceed expectations. Modern NDT systems offer traceable documentation and robust data analytics, empowering quality managers to make informed decisions and pursue continuous improvement. By embedding NDT into the quality management system, manufacturers gain streamlined workflows, reduced risk, and a competitive edge in demanding industrial environments.

NDT Methods for Semi-Finished Metal Components

Different NDT methods are suited to specific applications. Each offers unique benefits depending on the component shape, material, and inspection requirements:

1. Ultrasonic Testing with BARPROOF

This method uses high-frequency sound waves to detect internal defects in metal bars. The BARPROOF system, with phased-array ultrasonic technology, offers comprehensive coverage and exceptional sensitivity, enabling rapid, automated testing even in high-throughput environments.

With advanced signal processing, precise probe technology, and robust documentation, BARPROOF delivers consistent results. Its user-friendly interface, configurable programs, and adaptability to various bar dimensions make it essential for regulatory compliance, customer requirements, and productivity optimization.

2. Magnetic Flux Leakage Testing with CIRCOFLUX

This method magnetizes the metal and detects leakage fields caused by surface or near-surface discontinuities. CIRCOFLUX offers high-precision testing for ferromagnetic steel bars, enabling accurate and automated defect detection.

Equipped with robust sensors, CIRCOFLUX can detect cracks as small as 0.1 mm even at high speeds. Intelligent diameter adaptation and central adjustment reduce human error. Its integrated diagnostics and data management ensure traceability and compliance.

3. Eddy Current Testing with CIRCOGRAPH

Using electromagnetic induction, CIRCOGRAPH identifies surface and near-surface defects in wires, tubes, and bars. High-speed rotating heads and non-contact scanning allow for full 360° surface coverage, detecting defects as shallow as 30 µm.

The system supports automated, high-throughput testing at rates of up to 3 m/s, providing seamless, full-length inspection while minimizing handling effort. With intelligent clearance compensation and advanced digital analysis, CIRCOGRAPH delivers precise results regardless of material geometry or production speed. Its intuitive control interface, complete traceability, and secure data management simplify integration into modern quality assurance workflows, helping manufacturers comply with the strictest industry standards while maintaining peak operational efficiency and minimizing the risk of material failures in downstream applications.

FOERSTER CIRCOGRAPH

4. Material Mix Testing with MAGNATEST

This method uses magneto-inductive testing to check the material properties of semi-finished products. Magnatest ensures that the materials meet the required specifications, preventing material mix-ups and ensuring consistent quality. Through single-coil absolute mode and highly sensitive evaluation electronics, MAGNATEST can reliably detect even subtle differences in alloy composition, heat treatment status, or structural inhomogeneity.

The system’s automated sorting and statistical functions help manufacturers comply with stringent industry regulations, reduce manual inspection times, and optimize process integration. MAGNATEST's seamless data documentation and traceability capabilities further support audits and continuous process improvement, making it an indispensable component of an advanced quality management strategy for critical industrial applications.

5.Dimensional Testing with ZUMBACH

ZUMBACH uses laser and optical technologies to measure dimensions such as diameter, ovality, wall thickness, and concentricity in real time. Its non-contact system supports high-speed production and digital quality integration.

Real-time monitoring helps reduce off-spec material, support proactive control, and enhance data transparency, ensuring compliance and optimal product yield.

Choosing the Right NDT Solution for Your Manufacturing Needs

Selecting the right NDT method depends on component type, defect criticality, compliance needs, and automation levels. Manufacturers should consider test sensitivity, speed, traceability, and integration capabilities. Often, a hybrid approach combining multiple NDT methods provides comprehensive coverage, streamlined workflows, and lower total quality costs.

1. Bars

For the inspection of metal bars, ultrasonic testing with BARPROOF and magnetic flux leakage testing with CIRCOFLUX are exceptionally effective. Together, these methods ensure thorough detection of both internal and surface defects, offering a comprehensive quality control solution.

BARPROOF’s advanced phased-array ultrasonic technology provides high-resolution, real-time imaging of internal and near-surface flaws. It supports precise defect localization and quantitative analysis, even under challenging conditions with varying bar diameters. CIRCOFLUX complements this by delivering high-speed, non-contact detection of surface-breaking and subsurface defects across a broad range of materials and production speeds.

The integration of these two systems allows manufacturers to implement automatic defect sorting, fully traceable quality documentation, and seamless digital process integration. This combined approach facilitates rapid changeovers, reduces operator dependency, and consistently delivers audit-ready results—ensuring that only bars meeting the highest standards for safety, durability, and regulatory compliance proceed to downstream processing or shipment.

2. Wires

Eddy current testing using the CIRCOGRAPH system is a highly effective and non-destructive method for inspecting wires. In this process, a rotating probe surrounds the wire as it moves through the testing system. The method is based on the principle of electromagnetic induction: an alternating current passes through a coil, generating a fluctuating magnetic field. When a conductive material—such as a wire—enters this field, it induces eddy currents within the material.

Surface and near-surface defects—such as cracks, inclusions, or laps—disrupt the flow of these eddy currents, causing detectable changes in the coil's impedance. These variations are monitored and analyzed in real time.

The CIRCOGRAPH system provides full 360-degree coverage of the wire’s surface, ensuring high sensitivity to both longitudinal and transverse defects. This makes it particularly well-suited for continuous, high-speed production environments, enabling rapid, accurate, and reliable detection of imperfections.

As a result, manufacturers can consistently ensure that wires meet stringent quality standards prior to further processing or shipment.

3. Tubes

For the non-destructive inspection of tubes, both ultrasonic testing (UT) and eddy current testing (ECT) are widely used, depending on the material type, geometry, and the nature of the defects being evaluated.

Ultrasonic testing is particularly effective for detecting internal and volumetric defects such as inclusions, voids, and laminations. These systems use high-frequency sound waves that propagate through the tube wall and reflect back when they encounter discontinuities, enabling precise localization and sizing of internal flaws. In tube testing, conventional rotating ultrasonic systems are typically employed, whereas non-rotating phased-array systems are more common for bar testing.

Conversely, the CIRCOGRAPH system, based on eddy current testing, is optimized for identifying surface and near-surface defects—such as cracks, pits, or laps—especially in non-ferromagnetic tubes. The system uses rotating probes to scan the entire circumference of the tube, ensuring full 360° coverage in continuous inspection operations.

By combining both ultrasonic and eddy current testing methods, manufacturers can achieve thorough defect detection across the entire volume and surface of the tube. This dual approach ensures compliance with stringent industry standards and customer-specific quality requirements. These systems are particularly valuable in high-speed production environments, where consistent, accurate, and efficient quality control is essential.

The Role of Technology in Enhancing NDT Accuracy and Efficiency

Advancements in technology have significantly enhanced the accuracy, speed, and reliability of non-destructive testing (NDT) methods. Modern NDT systems now incorporate state-of-the-art sensors, advanced automation, and integrated data analysis tools, enabling more precise, consistent, and efficient inspections across a wide range of materials and components.

Innovations such as phased-array ultrasonic testing (PAUT), high-frequency eddy current testing (HF-ECT), and fully automated inspection systems have revolutionized traditional testing practices. These technologies offer faster scan rates, increased sensitivity to defects, and higher spatial resolution, allowing for earlier and more accurate detection of flaws.

In addition, automated data collection and analysis reduce the potential for human error and provide traceable, high-resolution inspection records. As a result, these advancements contribute to improved quality assurance, reduced downtime, and enhanced safety in critical applications across industries such as aerospace, automotive, energy, and manufacturing.

Future Trends in Non-Destructive Testing for the Manufacturing Industry

The future of non-destructive testing (NDT) in the manufacturing industry is poised for significant advancements, driven by emerging technologies and evolving industry demands. Key trends shaping this transformation include:

1. Artificial Intelligence

Artificial intelligence (AI) and machine learning (ML) algorithms are increasingly being integrated into modern NDT systems to greatly enhance defect detection, classification, and decision-making processes. These technologies can analyze vast amounts of inspection data—such as ultrasonic waveforms, eddy current signals, or radiographic images—with far greater speed and consistency than traditional methods.

By learning from historical inspection data, AI systems can identify complex patterns and subtle anomalies that might be difficult for human inspectors to detect. This results in improved detection accuracy, fewer false positives, and more consistent evaluations. Moreover, AI-powered NDT supports predictive maintenance, allowing potential issues to be identified and addressed before they lead to critical failures.

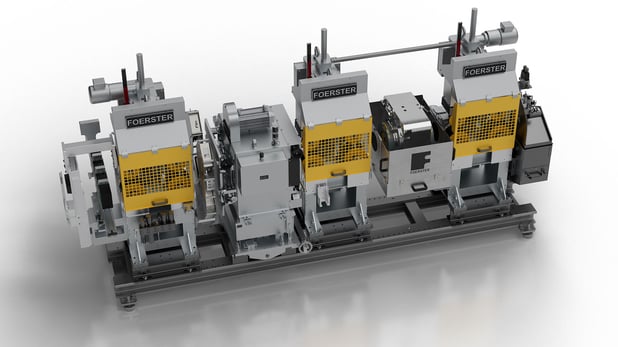

2. One-Stop Shop for NDT

There is a growing demand across the industry for comprehensive NDT solutions that consolidate multiple testing methods into a single, integrated platform. This “one-stop shop” approach enables manufacturers to perform a variety of inspections—such as ultrasonic testing, eddy current testing, magnetic particle inspection, and visual inspection—within a unified system.

By combining multiple NDT modalities, these integrated platforms streamline inspection workflows, reduce equipment redundancy, and minimize setup time, leading to significant gains in operational efficiency. Additionally, they facilitate centralized data acquisition, storage, and analysis—supporting improved traceability, real-time monitoring, and more effective quality control.

This all-in-one capability is particularly valuable in automated production environments, where high throughput, repeatability, and cost efficiency are essential. NDT providers that offer flexible, modular, and scalable solutions are well-positioned to meet the evolving needs of industries such as aerospace, automotive, energy, and metallurgy.

3. Business Solutions

Modern NDT providers are increasingly offering customized business solutions tailored to the specific requirements of different industries and production environments. Rather than relying solely on off-the-shelf systems, these providers work closely with clients to design application-specific inspection setups—including custom sensor configurations, mechanical adaptations, and workflow integration.

These solutions often feature specialized software packages that integrate seamlessly with existing production control systems, MES (Manufacturing Execution Systems), or quality management platforms. This enables real-time data sharing, automated defect reporting, and centralized quality tracking—critical for meeting both regulatory and operational standards.

Furthermore, comprehensive service packages—including installation, calibration, training, remote diagnostics, and long-term maintenance—ensure that NDT systems remain reliable and efficient throughout their lifecycle. These tailored, business-oriented offerings help manufacturers enhance inspection performance, reduce downtime, and maintain full compliance with industry-specific requirements and customer expectations.

4. Maintenance Contracts with Full-Service Providers

To ensure continuous reliability, accuracy, and performance of NDT systems, many manufacturers are entering into long-term maintenance contracts with full-service providers. These partnerships guarantee that inspection equipment is consistently maintained to the highest standards, helping to minimize downtime and extend system lifespan.

Such contracts typically cover regular calibration, preventive maintenance, on-site servicing, software updates, and technical support—each customized to the customer’s specific systems and operational needs. Some providers also offer remote diagnostics and predictive maintenance services, leveraging system data to proactively address issues before they impact production.

By outsourcing maintenance to experienced service providers, manufacturers benefit from assured system availability, streamlined regulatory compliance, and reduced internal resource demands. This full-service model is especially beneficial in high-throughput or safety-critical industries, where even brief inspection delays can lead to substantial operational or financial consequences.

Share this

You May Also Like

These Related Stories

.png?width=1920&height=1080&name=Blog%20Post%20-%20Large%20Hero%20Image%20(16).png)

Turnkey Automation: The Missing Link in Reliable Automated NDT

Tips for Detecting Weld Seam Issues After Scarfing in 2026