Axle pivots must withstand heavy loads. Therefore, high demands are placed on the material used. It is important to recognize material mixes and hardening errors so that only perfect material is installed. Non-destructive and automated crack and structure testing using eddy current supports continuous quality assurance.

FOERSTER offers the MAGNATEST product family for fully automated testing of material mixes and inspection of heat treatment conditions. In line with the customer‘s individual requirements, the MAGNATEST test instruments in combination with the corresponding test coils allow a 100% inspection of the axle pivots.

Fig. 1: MAGNATEST D with encircling test coil

Immediately after testing the axle pivots are automatically sorted into good and bad parts. In addition, the test results can be documented and forwarded to a higher-level quality management system for evaluation purposes.

The material surface of the axle pivots can also be inspected for surface defects such as cracks. Due to the modular structure of the test electronics, an individual adaptation to the production process is possible.

Fig. 2: STATOGRAPH CM+ with angled probes

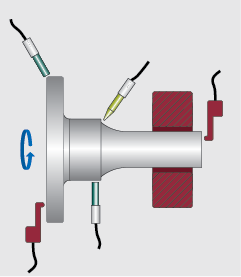

For crack detection of the critical zones of the axle pivots, the STATOGRAPH test instrument is used in combination with various standard and angled probes (see Figure 2). First, the single parts are rotated and the test zones are scanned for surface defects with the eddy current probes (see Figure 3). To additionally check heat treatment condition, a MAGNATEST encircling coil can be positioned in the pivot area.

Fig. 3: Example of defect and structure testing of axle pivots

Fig. 3: Example of defect and structure testing of axle pivots

For structure testing of axle pivots, we recommend the test instrument MAGNATEST with encircling coils for the detection of material mixes and hardening errors. The structure testing can be combined with defect testing with STATOGRAPH. Further information about our products and industry solutions can be found on our website: foerstergroup.com