In the past, fittings used in drinking water pipes have been made of brass. Following the tightening of the EU Drinking Water Ordinance, manufacturers switched to gunmetal. However, since this material is more susceptible to surface defects such as cracks, a continuous control of product quality is necessary in the running process.

FOERSTER has developed flex probes for eddy current testing in order to enable a high error resolution even in components with complex geometries such as fittings. The flex probes can be adapted to almost any shape. In combination with the STATOGRAPH CM+ test system, even the finest cracks in fittings can be detected. The non-destructive eddy current method is based on the comparison with reference defects.

.jpg?width=386&height=163&name=Blog4(3).jpg)

Figure 1: STATOGRAPH CM+ and Flex probes

In the following, a reference defect of 0.2 mm in depth was eroded at the bead of a fitting. A flex probe, specially adapted to the bead, with a spur width of 3.6 mm is perpendicular to the surface being tested. The flex probe is fitted into a probe holder. Testing is fully automated in the running process. Subsequent to the testing, the fittings are automatically sorted into good and bad parts.

.jpg?width=388&height=310&name=Blog%204(2).jpg)

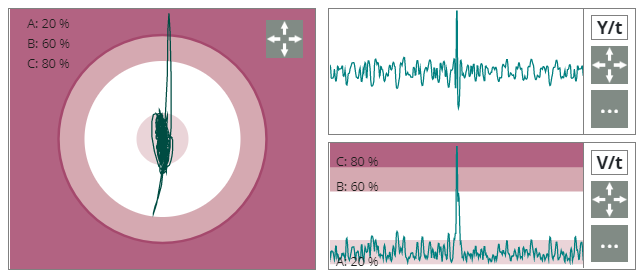

Figure 2: Reference defect and top view of flex probe

The reference defect can be clearly seen in the signal image as a crack error at a signal to noise ratio of 3:1, see Fig.3.

Figure 3: Test result

Figure 3: Test result

Since the flex probes can be adapted to different fittings according to customer requirements, a reliable surface testing for defects is possible. This ensures that the end customer receives the material in the desired product quality.

We recommend the STATOGRAPH CM+ test system in combination with a flex probe for the crack detection of fittings. This combination allows the detection of even the finest cracks in the material surface and ensures product quality. For further information, please visit our website at: foerstergroup.com