The detection of ferromagnetic inclusions is useful in different industry domains: textile, food, chemical, medical, drugs, geophysics, space applications and electrical conductor manufacturing.

While the adverse effect of ferromagnetic inclusion seems obvious in food or textiles or medicines or even geophysics and space, it may be less obvious in the application of electrical conductor or electrical wire manufacturing. In this article we are addressing the application of ferromagnetic inclusion detection in copper rods in Continuous Cast and Rolling lines.

Demand increase for finer wires

Wire rod produced in a Continuous Casting and Rolling (CCR) mill is drawn down to smaller diameter wire products for various applications. Starting at about 8 mm in a CCR mill, the wire rod is drawn to smaller diameter, often down to 40 or 50 microns.

There are many electrical and electronic appliances and devices today where finer and finer wires of superior quality are required due to limitations in size. Going forward this requirement will only increase. To achieve the reduction required to produce these fine wires, the ductility / drawability of the wire rod is of great importance.

The importance of detection ferrous inclusions at earliest stage

Ferrous inclusion in the wire rod reduces the ductility of the copper wire rod and thereby affects its drawability adversely. Therefore, detection of ferrous inclusions at the earliest stage of manufacture becomes more and more important and necessary.

In a CCR mill, the ferrous inclusions could be on the surface of the wire rod or buried deep inside depending on the source of the inclusion. While ferrous inclusion at the core cannot be ruled out, most of the ferrous inclusions occur on the surface or get embedded below the surface.

Research studies on the effects and of these inclusions and their sensitivity vis-à-vis inclusion size, proximity of inclusions continue to be carried out keeping in line with the demand of finer and finer wires.

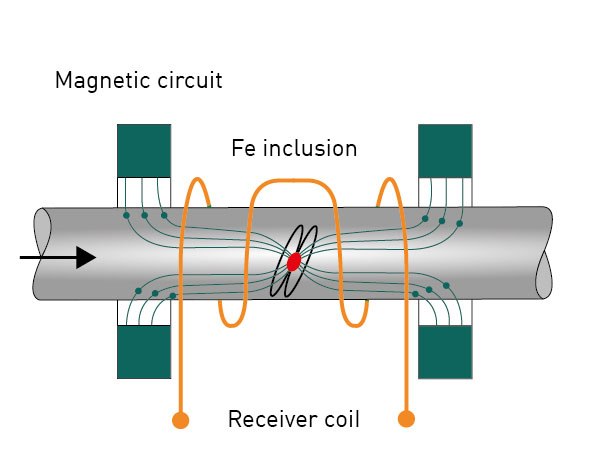

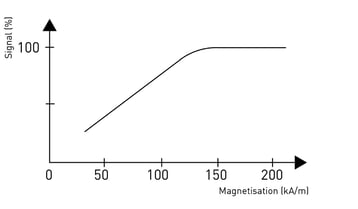

The principle of the technique is shown below.

Continious Casting and Rolling lines in ferrous inclusion detection

Continious Casting and Rolling lines in ferrous inclusion detection

Principle of Magneto-Inductive detection of ferrous particles

Principle of Magneto-Inductive detection of ferrous particles

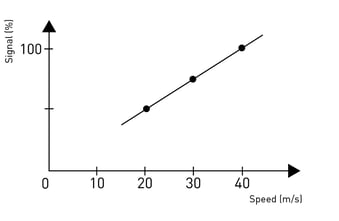

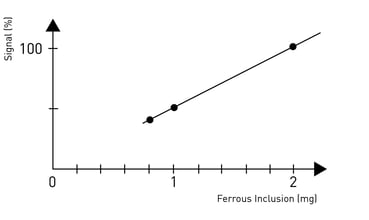

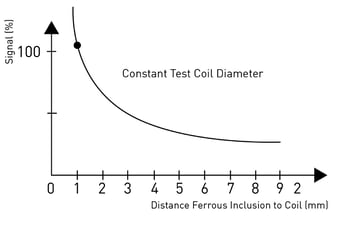

Some relationships

The magneto-induction technique is a very reliable and repeatable technique to detect extremely small ferrous inclusions embedded even at the core of wire rod. The smallest inclusions could be as small as 67 microns.

| Test coil |

Worst case

(located at the core) |

Best case

(located on the surface) |

| |

mg mm |

mg mm |

| 0,6 mm |

0,025 0,138 |

0,0013 0,067 |

| 1,0 mm |

0,07 0,257 |

0,0035 0,095 |

| 2,0 mm |

0,20 0,365 |

0,01 0,134 |

| 2,6 mm |

0,40 0,46 |

0,02 0,17 |

| 7 mm |

1,2 0,66 |

0,06 0,244 |

| 9 mm |

1,8 0,76 |

0,09 0,28 |

| 11 mm |

3,0 0,90 |

0,15 0,33 |

| 13 mm |

3,6 0,96 |

0,18 0,36 |

Table showing detectability versus inclusion size

FOERSTER FERROMAT Channel can be added on any CCR lines on their standard FOERSTER Eddy Current instrumentation on existing lines like Southwire, Properzi, Outokumpu, Contirod etc.