Qualification of soft magnetic steels for the manufacturing of electromagnetic actuators and sensors

In the automotive industry there is a steady growth of the quality requirements for soft magnetic steels supplied to produce various components used for actuators, sensors, or electrical machines. One frequent example is the solenoid valve that in general can be applied both as an actuator and a sensor. The solenoid valves are widely applied in the automotive industry, i.e. being a part of the moving or controlling mechanism with an objective of fast and efficient electromagnetic energy transformation into mechanical action or vice versa. To achieve transformation and functional efficiency, soft magnetic permeable steels as basis material are needed. In order to meet the efficiency requirements, soft magnetic steel suppliers and component manufactures have to qualify their underlying materials (e.g. ferritic stainless steel) with pre-specified ferromagnetic characteristics.

What are the key ferromagnetic characteristics in demand?

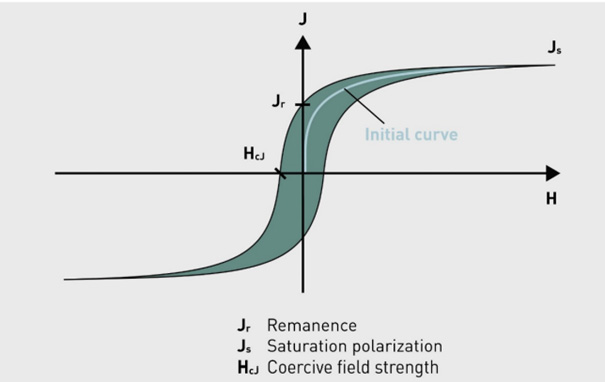

The ferromagnetic characteristics being considered in qualifying soft magnetic materials are typically represented by the DC magnetic hysteresis curve. The hysteresis curve includes, but not limited to, such single physical quantities as coercivity (HcJ), magnetic saturation polarization (JS) and relative permeability (μr).

Hysteresis loop

Hysteresis loop

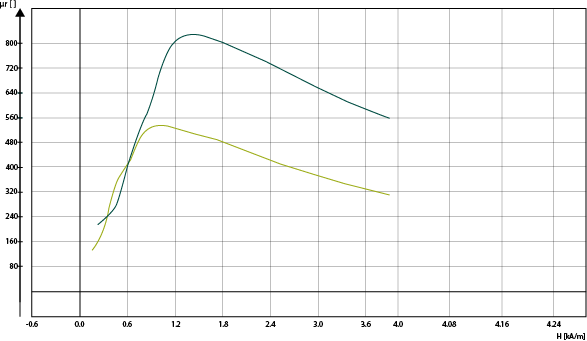

The relative permeability is one of the well acceptable parameters to characterize the “magnetic softness” of ferromagnetic materials. The relative permeability µr is proportional to B/H ratio and shows the steepness of the initial curve in the B(H) diagram. It characterizes how dynamically efficient a dedicated material performs in a dynamic in the magnetization process. The higher the relative permeability µr, the faster the components (made from this material) in the electromagnetic system can be magnetized, which contributes to increasing the system’s dynamics.

The relative permeability µr is not a constant parameter for ferromagnetic materials and depends on the magnitude of the applied magnetic field strength (H). Therefore, it is not unusual that for simplicity reasons often only the maximum value of relative permeability curve (μrmax) is considered.

Relative permeability as a function of H for 2 sample types

Relative permeability as a function of H for 2 sample types

The relative permeability can be greatly altered during soft magnetic material manufacturing, i.e. after drawing, rolling, grinding and annealing processes. As an example, for stainless steels like 1.4105 or 1.4106, being broadly used to produce actuators or sensors in the automotive industry, the level of μrmax could vary in the range between 700 and 1800 depending on machining or heat treatment condition.

Open magnetic circuit method and KOERZIMAT J-H

One of the frequent forms of supplied soft magnetic steels is round bars or rectangular sheets. To measure μrmax, both steel suppliers and buyers are looking for a precise industry device, but with a simple functionality and not requiring sophisticated sample preparation.

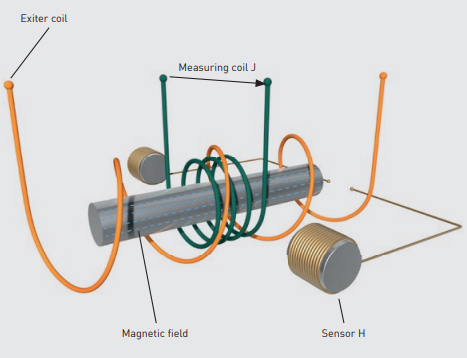

The hysteresis curve can be measured time and resource efficiently with the method of the magnetisation in the open magnetic circuit. The advantage of the method is that no additional mechanical adaptation and preparation (e.g. grinding, clamping) is required, but only predefined scale dimension of the sample needs to be adhered.

KOERZIMAT J-H technology

KOERZIMAT J-H technology

Based on this method, to test soft magnetic round bars and sheets FOERSTER developed the KOERZIMAT 1.097 J-H System. The KOERZIMAT J-H System enables measurement of the complete hysteresis loop. This system allows to measure the hysteresis loop and relative permeability without additional mechanical adaptation and load required for tested specimen.

For the measurement the sample is inserted into the sense coil of the sample holder, which then is placed inside the coil. The design ensures that the sample is placed centric within the homogenous region of the field coil. Before the start of the measurement the sample is demagnetized. The following hysteresis measurement is controlled by the KOERZIMAT controller, which ensures long enough measurement times to avoid side effects from eddy currents and enables hysteresis measurements up to 100 kA/m.

KOERZIMAT J-H Device

KOERZIMAT J-H Device

Hysteresis measurements in an open magnetic circuit are affected by demagnetization effects, which can be corrected mathematically. Correction for demagnetization is automatically carried out by the J-H software via calculations of the fluxmetric demagnetization factors; the measurement results are displayed in the form of the “true”, sheared hysteresis.

Which materials can be measured?

The KOERZIMAT J-H is designed for soft magnetic materials and can measure a hysteresis loop with a maximum field strength of 100 kA/m. Applying the implemented demagnetization correction show good agreement with standardized measurements and literature data in the permeability range of 100 – 4000.

English Youtube video for KOERZIMAT J-H

Share this

You May Also Like

These Related Stories

Material inspection for reed switch production

Magnetic properties of materials and components