Choosing the Right Sensor for Your Eddy Current Testing

In non-destructive testing (NDT), the ability to detect surface and near surface defects depends on one critical component: the sensor.

Sensors in eddy current testing convert the material’s response into clear data, making it easier to spot flaws before they turn into failures.

At FOERSTER, sensors are at the heart of every solution. Since 1948, we have helped manufacturers ensure safety and reliability through advanced eddy current, magnetic, and detection technologies. Our sensors provide precision and consistency so you can feel confident in your product’s quality.

Why Sensors Matter in NDT

Sensors are where meaningful inspection data begins. A high-quality sensor detects the smallest signal changes in a material’s electromagnetic response, capturing information about cracks, inclusions, structural variations, or material inconsistencies.

That level of performance is why FOERSTER offers a comprehensive range of standard and customized sensors, probes, and coils, each designed for specific applications, materials, and manufacturing environments.

Types of Sensors Used in Eddy Current Testing

Every testing challenge is different. The right sensor ensures accurate data, efficient testing, and reliable results. FOERSTER provides three main sensor types to meet diverse inspection needs.

Standard Sensors

Standard sensors form the foundation of many eddy current testing systems. They inspect one region at a time, offering focused, repeatable results. These sensors are ideal for:

- Continuous inspection of wires, bars, and tubes using encircling coils

- Single-point testing of machined components or welds

- Routine quality checks with precision and consistency

Their simplicity and reliability make standard sensors the preferred choice for many production environments.

Custom Sensors

Custom sensors are developed for complex geometries, specialized materials, or unique production setups. Common applications include:

- Component testing for automotive, aerospace, or energy parts

- Specialty manufacturing processes where space, shape, or magnetic properties require a tailored approach

FOERSTER works directly with clients to develop individualized new solutions specifically tailored to your application needs.

Array Sensors

Array sensors represent the next evolution in eddy current testing. Multiple sensing elements are combined in a single housing to collect data from multiple sensor elements or channels at once. This configuration reduces inspection time and increases both data density and defect visibility. Key advantages of array sensors include:

- More test coverage per scan path with detailed c-scan results for easy evaluation

- Positionally accurate readings that help pinpoint exact flaw locations via the use of encoders

Array technology is a valuable resource for mobile, hand-held inspections, where you need to cover large surface areas and navigate complex geometries quickly and reliably.

.png?width=252&height=168&name=TS_DA-16_Array_LS_3078%20(1).png) It is equally valuable for long product testing, such as bars and tubes. By using multiple sensor elements, array systems can detect smaller defects and provide precise positional information, including where the flaw sits around the circumference of the product.

It is equally valuable for long product testing, such as bars and tubes. By using multiple sensor elements, array systems can detect smaller defects and provide precise positional information, including where the flaw sits around the circumference of the product.

How FOERSTER Leads in Sensor Technology

At FOERSTER, we know that every application is unique. Each of our sensors is handcrafted under magnification by our highly trained specialists and built into robust housings that withstand the demands of industrial use.

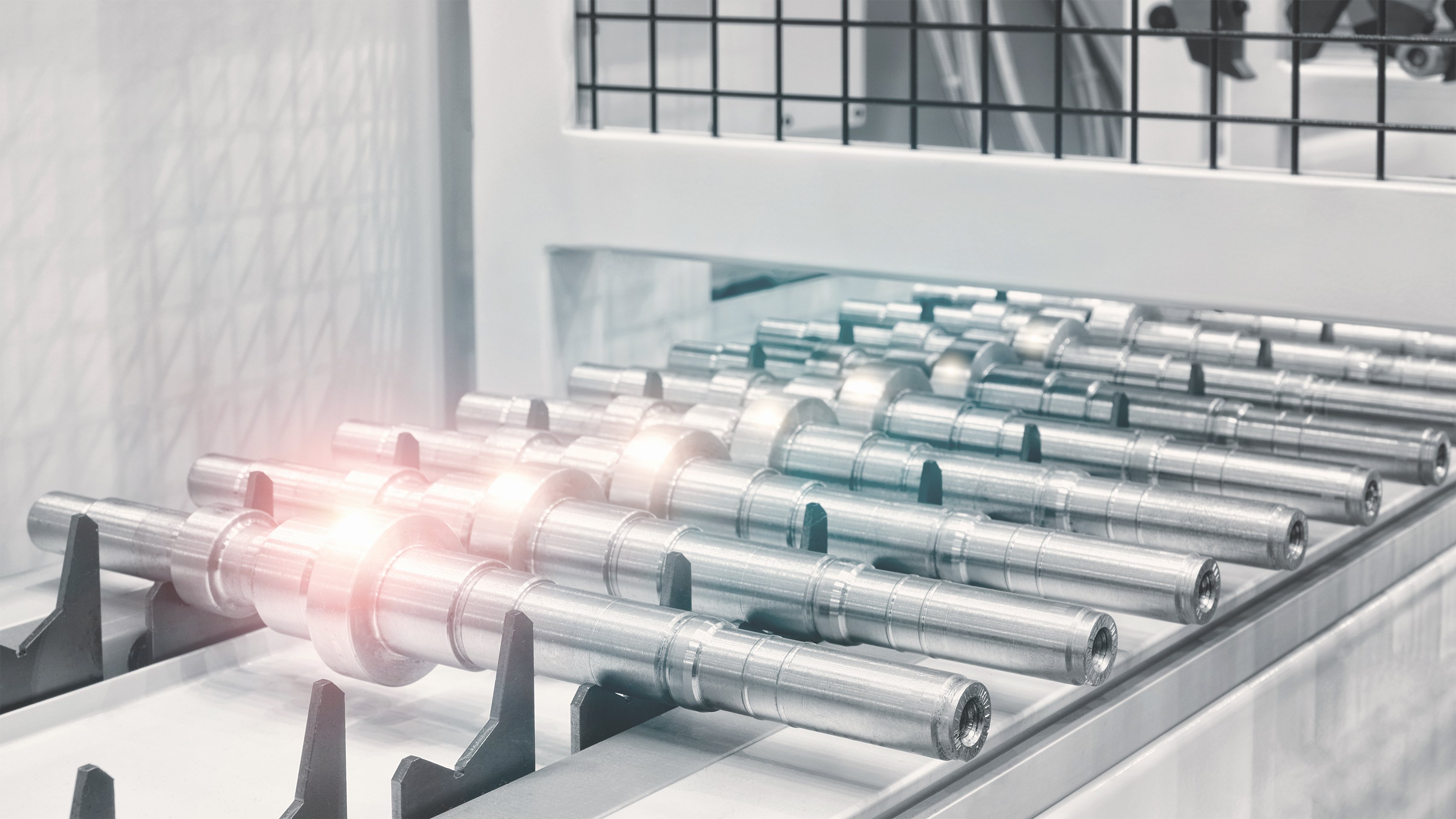

.jpg?width=252&height=168&name=Anwendung%201%20(1).jpg)

By integrating these sensors into systems such as the DEFECTOMAT DA and TCM 2.142, FOERSTER helps customers achieve:

- Complete coverage of every part or product

- Real-time visualization of detected flaws

- Faster, data-driven decision-making

- Traceable results that support compliance and digital transformation

Actionable Takeaways: Choosing the Right Sensor for NDT

When selecting a sensor for your NDT process, consider the following factors:

- Part geometry: Flat, round, or contoured surfaces determine the best sensor design.

- Material type: Conductivity and magnetic properties affect signal behavior.

- Inspection goal: Define whether you are verifying integrity, locating cracks, or mapping structural changes.

- Testing environment: Inline systems and portable solutions require different sensor configurations.

Whether you need a single-coil sensor for standard testing, a custom probe for specialized components, or an array sensor for large-scale data capture, FOERSTER delivers precision-engineered solutions that make invisible flaws visible.

At FOERSTER, sensors are not just part of the system. They are the heart of it.

Share this

You May Also Like

These Related Stories

Advanced Eddy Current Testing for Freight Wagon Wheels

Automated testing of cylinder bores with the eddy current method