Freight wagon wheels endure constant mechanical and thermal stress, making them vulnerable to surface cracks, rolling contact fatigue, and thermal-induced damage. Traditional methods like Magnetic Particle Inspection (MPI) have been reliable but time-consuming, involving multiple handling steps that interrupt workflows.

Eddy Current Testing (ECT)—especially when integrated directly into the wheel reprofiling machine—provides a faster, more efficient, and non-destructive testing (NDT) solution.

This blog highlights how FOERSTER’s TCM system with ECARRAY technology transforms railway maintenance through automated, real-time wheel defect detection.

The Challenge: Surface Cracks in Freight Wagon Wheels

Freight wheels operate under harsh conditions. Over time, this leads to wear, material fatigue, and ultimately safety risks.

Common Defect Mechanisms:

-

Rolling Contact Fatigue: Microcracks from cyclic stress evolve into surface spalling.

-

Thermal Stress: Frequent braking leads to rapid heating/cooling, triggering structural changes and cracks.

-

Mechanical Wear: Continuous friction degrades material, increasing the risk of flaws.

Early flaw detection is essential not just for safety, but also for cost-effective, long-lasting wheel use.

The Solution: Eddy Current Testing for Surface Crack Detection

ECT uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. It is:

How It Works:

A probe generates alternating current, producing a magnetic field. When placed near a conductive material (like a steel wheel), it induces eddy currents. Defects interrupt these currents, which the system captures and analyzes.

In Practice: Why Eddy Current Testing outperforms Traditional Methods

ECT Advantages in Freight Rail Maintenance

-

Inline integration: Directly embedded into the reprofiling machine, eliminating manual handling

-

Real-time analysis: Immediate defect feedback, no inspection delay

-

No consumables: No developer, film, or magnetic particles needed

-

Preserves material: Precise flaw depth info prevents unnecessary wheel grinding

Case Study: FOERSTER’s TCM with ECARRAY in Real-World Use

A validation study with W.S. Werkstoff Service GmbH demonstrated outstanding ECT performance on simulated wheelset defects.

Setup:

-

Master test wheel with artificial grooves (10 mm × 1.0 mm and others)

-

FOERSTER’s TCM system with ECARRAY technology

-

Customized 64-element array probe for full-surface coverage

Key Probe Features:

-

Tailored contour matching the wheel profile

-

2.2 mm sensor pitch for high resolution

-

Flexible mount for consistent surface contact

-

Full coverage of running surfaces and transition zones

Results:

-

Accurate flaw detection including <1.0 mm cracks

-

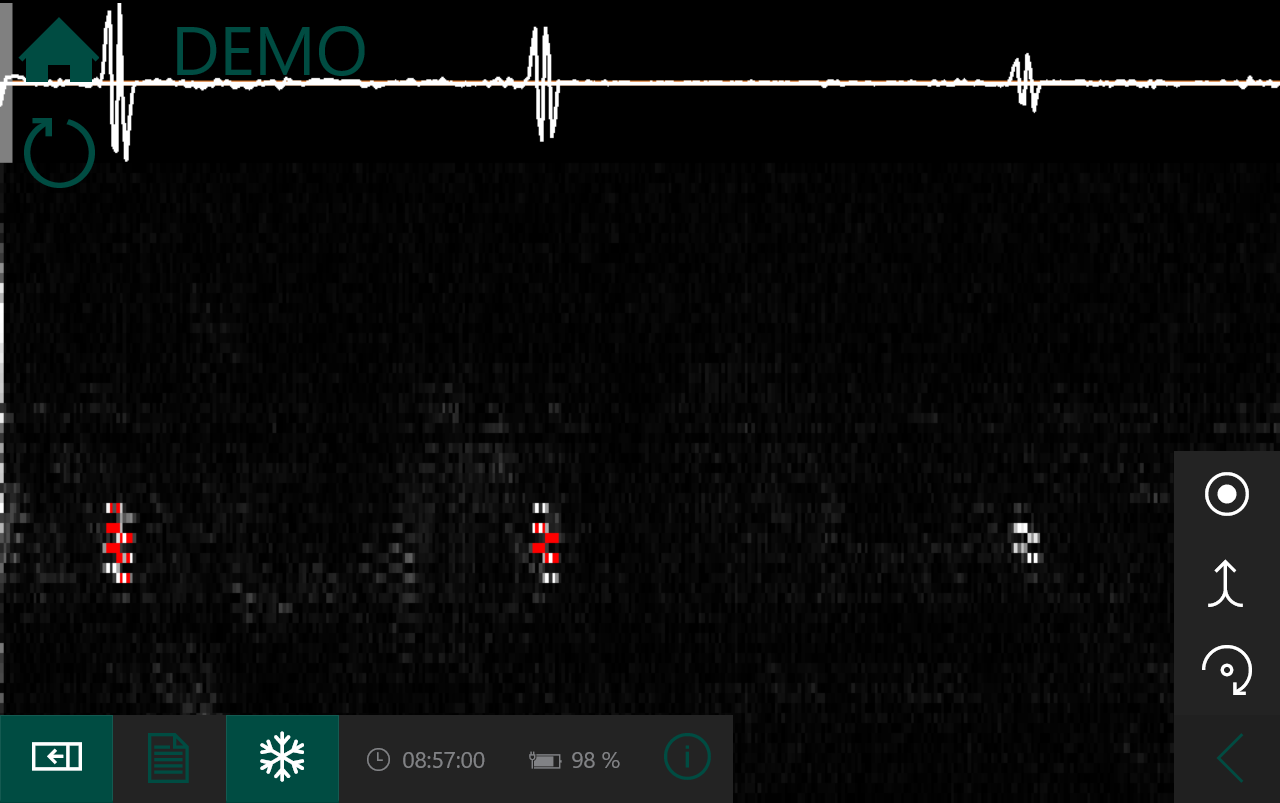

Defect visualization via ECARRAY’s impedance display

-

Stable signal quality even over multiple wheel rotations

Benefits for Maintenance Teams

Less Handling Effort – No wheel disassembly or remounting

Faster Turnaround – Real-time inspection during reprofiling

Zero Consumables – Environmentally friendly, lower cost

Longer Wheel Life – Optimized defect detection avoids unnecessary material removal

TCM by FOERSTER – Eddy Current Testing for Rail Safety

.jpg?width=1592&height=1428&name=DSC04497_bearb%20(3).jpg)

FOERSTER’s TCM system with ECARRAY delivers a fully integrated, high-performance Eddy Current Testing solution for freight wheel inspections.

- Flaw detection down to 0.5 mm depth

- Inline operation—no workflow interruptions

- Objective, digital results in real time

- Proven performance under real-world conditions

Ready to Upgrade Your Wheel Inspections?

Optimize your railway maintenance with FOERSTER’s leading non-destructive Eddy Current technology.

Contact our experts today to discuss your specific application needs or schedule a demo.