Brake discs are safety-relevant components, and one of the most important pieces of a car. The quality requirements for the materials used are high, as the kinetic energy of the vehicle is completely converted into heat. Brake discs must therefore be able to withstand mechanical stresses caused by compressive and tensile forces during braking, thermal loads, and centrifugal forces at high wheel speeds. On this account, it is crucial for brake discs to be 100% error-free.

Why should you check brake discs for cracks?

Even the smallest flaws in the material surface can quickly expand into large cracks during operation and become a risk to safety. This is fostered by high forces and temperatures of up to 700 °C (1300 °F). Consequently, cracks or interfering contours on the brake disc must be detected during the manufacturing process. These often occur on certain points of the part due to the production process, such as through casting or heat treatment of the disc.

How can the smallest cracks on brake discs be detected?

In order to find longitudinal, short, and transverse flaws on the material surface, a fully automatic crack detection instrument is commonly used in the production line. Via an excitation coil, an alternating magnetic field is induced. A differential receiver coil measures the change in eddy current density. Highly sensitive probes detect the cracks 100 percent. For this purpose, the test instrument compares the cracks with reference errors.

Statograph® product family

How does crack detection work in series production?

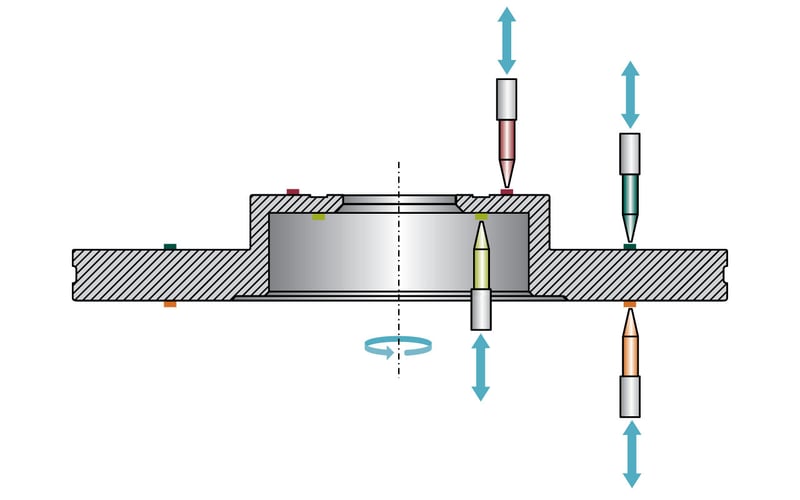

During the testing process, error-prone areas on the outside and inside the braking and mounting surfaces are examined. Automated testing makes it possible to test several hundred parts per hour.

As seen in figure 3, the test concept of a brake disk shows the scanning range of the four different probes. With probes adapted to the material, a sensitive and reproducible test can be performed.

Testing principle on a brake disc

Once the test is carried out, good and bad parts are automatically sorted. To ensure continuous quality, the results are documented and stored in the testing software. Detailed documentation supports quality assurance.

Your fully automated test solution for brake discs

The STATOGRAPH test system coupled with an appropriate set of probes is used to identify cracks on brake disks. STATOVISION is a software designed to support the documentation process. This combination enables you to recognize errors at an early stage and continuously monitor the quality of your product. You can find more information on our homepage at foerstergroup.com