Assessing Magnetic Properties in Soft Magnetic Steels & Powder Metallurgy Components

Soft magnetic steels and powder metallurgy components are crucial in industries such as automotive, energy, and industrial manufacturing. Accurately measuring their magnetic properties ensures optimal performance, quality control, and compliance with industry standards. FOERSTER's KOERZIMAT system, including the HCJ module, provides high-precision measurements, helping manufacturers achieve consistency and reliability in their products while offering advantages over competing systems.

Soft Magnetic Steels: Why Magnetic Property Measurement Matters

1. Quality Control of Soft Magnetic MaterialsSoft magnetic steels are widely used in electric motors, transformers, and inductors. Their key performance characteristics—such as permeability, coercivity (HCJ), and saturation magnetization—must be controlled to ensure efficiency and minimize energy losses. KOERZIMAT provides precise measurement of these properties, helping manufacturers optimize material selection and processing.

2. Optimizing Alloy Composition and Processing

The magnetic performance of soft magnetic steels depends on their composition and heat treatment. KOERZIMAT allows manufacturers to assess:

- Saturation Magnetization: Ensures optimal material selection for different applications.

- Coercivity (HCJ): Determines a material’s resistance to magnetization reversal.

- Hysteresis Losses: Identifies materials with lower energy dissipation.

Compared to competitor devices, which rely on Hall probes and produces position-dependent measurements, KOERZIMAT HCJ follows IEC 60404-7 Method B, ensuring integral and highly reproducible measurements.

3. Evaluating and Validating Sintered Components in Powder Metallurgy

Powder metallurgy is widely used to produce soft magnetic components with complex geometries, requiring precise testing to ensure optimal performance. The KOERZIMAT system, equipped with its HCJ module, plays a crucial role in both evaluating sintered materials and validating new manufacturing processes.

Key Benefits:

- Ensuring Material Quality – Detects variations in binder content, grain structure, density, and processing defects that impact magnetic performance.

- Accurate Characterization – Unlike the competing hall probe equipment which struggle with complex shapes, KOERZIMAT HCJ and MS 1.097 measure integral values with superior fluxgate-magnetometer technology, providing more reliable results.

- Supporting Innovation – As new soft magnetic materials and processes (e.g., additive manufacturing of magnetic alloys) emerge, KOERZIMAT delivers precise data, enabling material refinement and process optimization.

4. Compliance with Industry Standards

Soft magnetic materials must adhere to strict standards, such as:

- ASTM A804/A804M for soft magnetic iron and alloys.

- IEC 60404-14 for magnetic properties of soft magnetic materials.

KOERZIMAT ensures compliance, helping manufacturers meet certification and regulatory requirements. Unlike some competitor systems, KOERZIMAT’s shielding design suppresses external magnetic field interference, ensuring precise and standardized measurements.

5. Application in Key Industries

- Automotive – Fuel injection and ignition systems as well as motor cores, inductors, and transformer cores in EV.

- Power and Energy – Transformers, inductors, and generators

- Aerospace & Defense – Precision control systems for aircrafts and high-frequency performance in radar & navigational equipment.

- Medical Technology – Implanted medical sensors, surgical instruments, hearing aids, and key components for MRI machines.

- Industrial Automation & Robotics – Magnetic clutches & brakes, servo drives and motors.

6. Ensuring Long-Term Reliability & Performance

KOERZIMAT ensures consistent magnetic properties by measuring saturation magnetization and coercivity (HCJ), enabling manufacturers to maintain batch-to-batch uniformity. This helps predict long-term performance, improving the reliability and durability of components in automotive, energy, and other critical applications.

7. Advantages Over Competing Systems

KOERZIMAT offers several advantages over competitor devices such as:

- Higher Max Magnetization Field: KOERZIMAT HCJ can apply fields up to 450 kA/m, compared to other available equipment which are only capable of fields below 150 kA/m, allowing KOERZIMAT to accurately measure across a wider range of coercivities.

- Integral Measurement Approach: Unlike devices using Hall probes, KOERZIMAT’s fluxgate-based method ensures full-specimen measurement, minimizing positional errors.

- Measurement of Small Components: KOERZIMAT MS 1.097’s high sensitivity enables the measurement of small parts down to 0.1mg Co with superior accuracy.

- Fast and Efficient Testing: KOERZIMAT performs HCJ and MS measurements in 3-4 seconds each, much faster than competing systems, allowing integration into production environments.

Key Magnetic Properties Measured by KOERZIMAT

- Saturation Magnetization (Js): Determines weight-specific and volume-specific saturation polarization, indicating maximum capable magnetization of ferromagnetic materials.

- Coercivity (HCJ): Measurement of applied magnetic field required to bring material magnetization back to zero.

- Hysteresis Loop Properties: Evaluates complete J-H hysteresis loop, including the initial magnetization curve, in soft magnetic steels, giving insights into magnetic behavior under varying field strengths.

- Relative Permeability: Evaluates the degree of magnetization of a material in response to an applied magnetic field, indicating how easily a material allows magnetic field lines to pass through it.

Conclusion

Assessing the magnetic properties of soft magnetic steels and powder metallurgy components is critical for ensuring efficiency, reliability, and compliance with industry standards. KOERZIMAT by FOERSTER, including its HCJ module, provides precise, reliable measurements, helping manufacturers optimize processes, develop new materials, and enhance product performance. By integrating KOERZIMAT into quality control and R&D efforts, industries can achieve superior energy efficiency and sustainability while benefiting from a superior measurement approach compared to competitors.

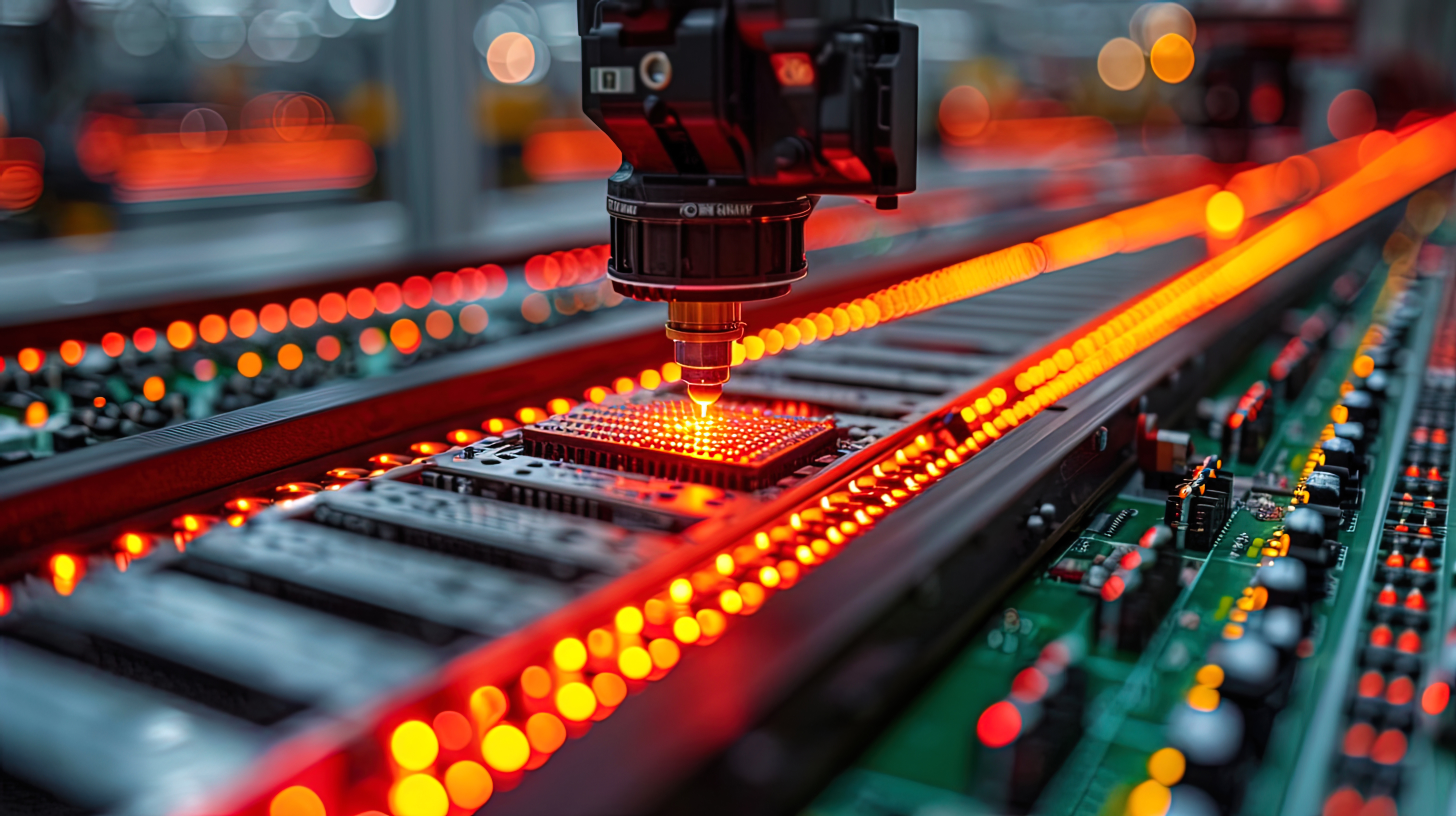

Lastly, the KOERZIMAT 1.097 HCJ/J-H can be integrated into fully automated, turn-key solutions, enhancing efficiency and consistency in quality control processes. This capability allows for seamless operation within automated production cells, ensuring continuous monitoring and documentation of material properties.

Share this

You May Also Like

These Related Stories

Decoding Coercivity & Magnetic Saturation Testing: Industry Significance

Magnetic properties of materials and components