In the precision engineering and manufacturing industry, powdered metal is highly valued for its versatility, durability, and cost-effectiveness. However, powder metal components are prone to defects due to the pressing, sintering, and machining processes involved in their creation. Typical flaws include chipped teeth or circumferential cracking at the root of the tooth, cracking around a hub, and even between weight reduction holes in the gear.

Though this post focuses on powder metal components, the detectability and effectiveness of eddy current testing applies to other forms of gear manufacturing such as forging and machining.

The Role of Eddy Current Testing in Gear Manufacturing

Eddy current testing (ECT) has revolutionized the inspection process for critical components like gears. This non-destructive testing method is especially valuable for high-volume gear production, ensuring that stringent quality standards are met. By integrating ECT into quality assurance processes, manufacturers can minimize the risk of costly recalls and failures, improve product reliability, and save on scrap costs.

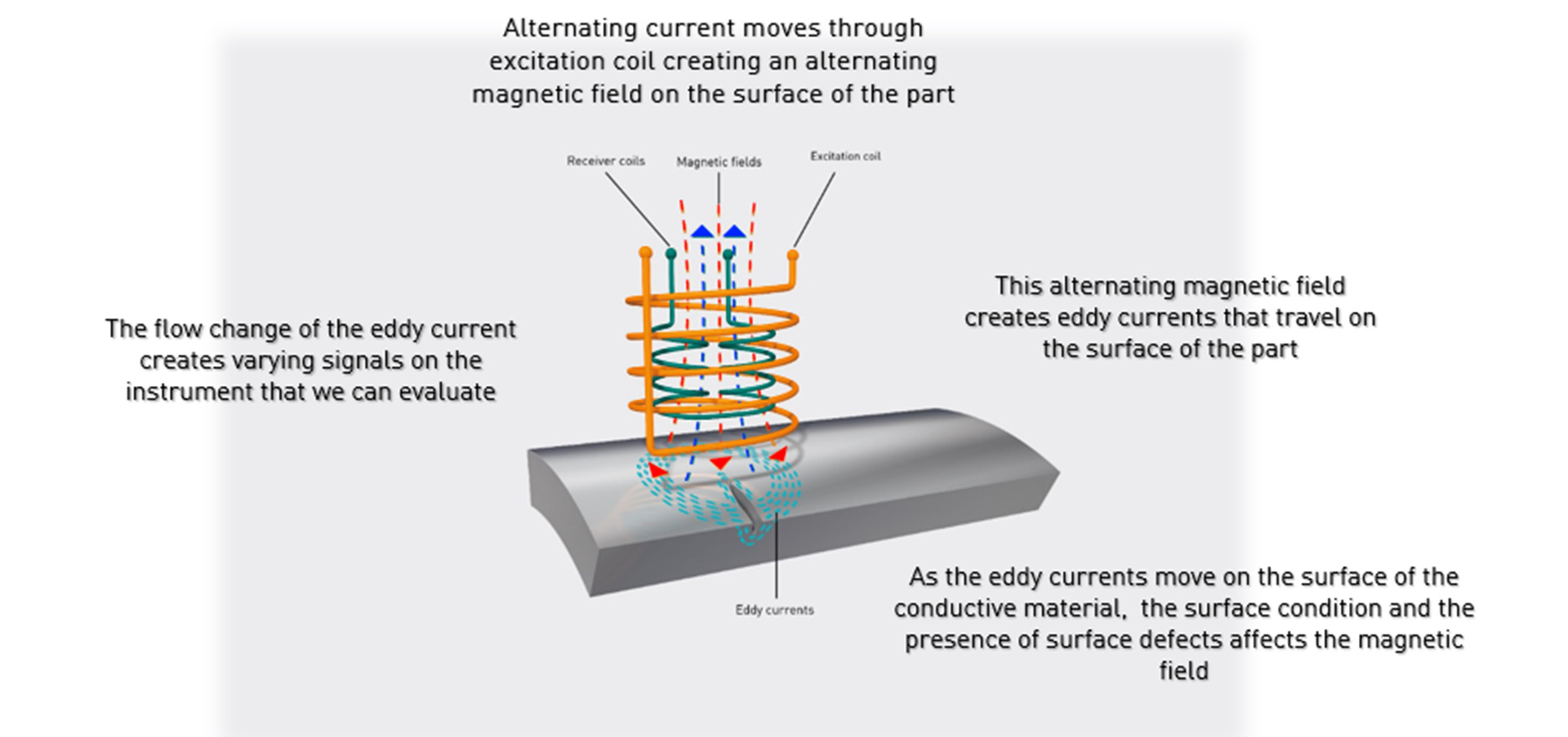

How Eddy Current Testing Works

ECT utilizes electromagnetic induction to detect surface and near-surface flaws in conductive materials. For gears, this means inducing eddy currents in the material and analyzing changes in their electromagnetic fields. Defects such as cracks, chips, and inconsistencies can be detected before assembly.

Low-frequency eddy current testing, also known as magneto-induction, can verify different types of metal processing and material characteristics. By simply placing or passing a part through an encircling coil, properties such as heat treatment, hardness, case depth, and alloy composition can be assessed.

Benefits of Eddy Current Testing

- Enhanced Reliability: Ensures the reliability of gears by swiftly pinpointing imperfections.

- Manufacturing Efficiency: Enhances manufacturing efficiency by identifying defects at full production speeds.

- Cost Savings: Reduces the risk of recalls and failures, saving manufacturers high costs due to scrap.

- High Standards: Adheres to stringent quality standards, ensuring gears excel in demanding applications across various industries.

Practical Application Example

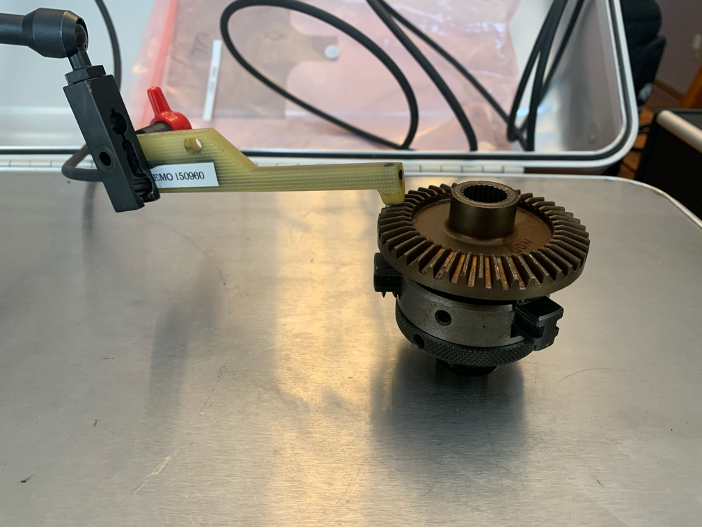

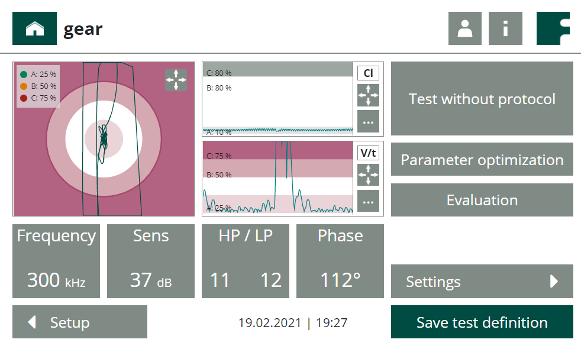

The image below outlines a gear tooth testing example and the accompanying instrument readings that determine if a part is nonconforming. By rotating the gear and positioning a differential probe near the desired test area (in this case, the top of the gear teeth), higher amplitude signals on the instrument confirm that this specific part is defective. With the use of eddy current testing and complementary material handling, full inspection and sorting can be completed while adhering to production speed requirements.

Example of crack signals on STATOGRAPH CM

Conclusion

Eddy current testing of gears is an effective nondestructive inspection method used to detect surface and near-surface defects such as cracks, chips, and material variation. It is a valuable tool for gear manufacturers, offering precise, real-time feedback that allows for the highest standards of performance and durability. This technique involves inducing electric currents, known as eddy currents, into the gear material using a probe. Variations in the eddy currents caused by defects affect the electromagnetic field, which is detected and analyzed by the testing equipment.

Eddy current testing is valued for its sensitivity, objective consistency, and ability to inspect complex geometries without requiring direct contact. It is an extremely effective tool for maintaining the reliability and safety of critical components such as gears in various industries, including aerospace and automotive.