Safeguarding FOERSTER Inspection Equipment for Long-Term Protection

The Harsh Reality of Mills and Plants

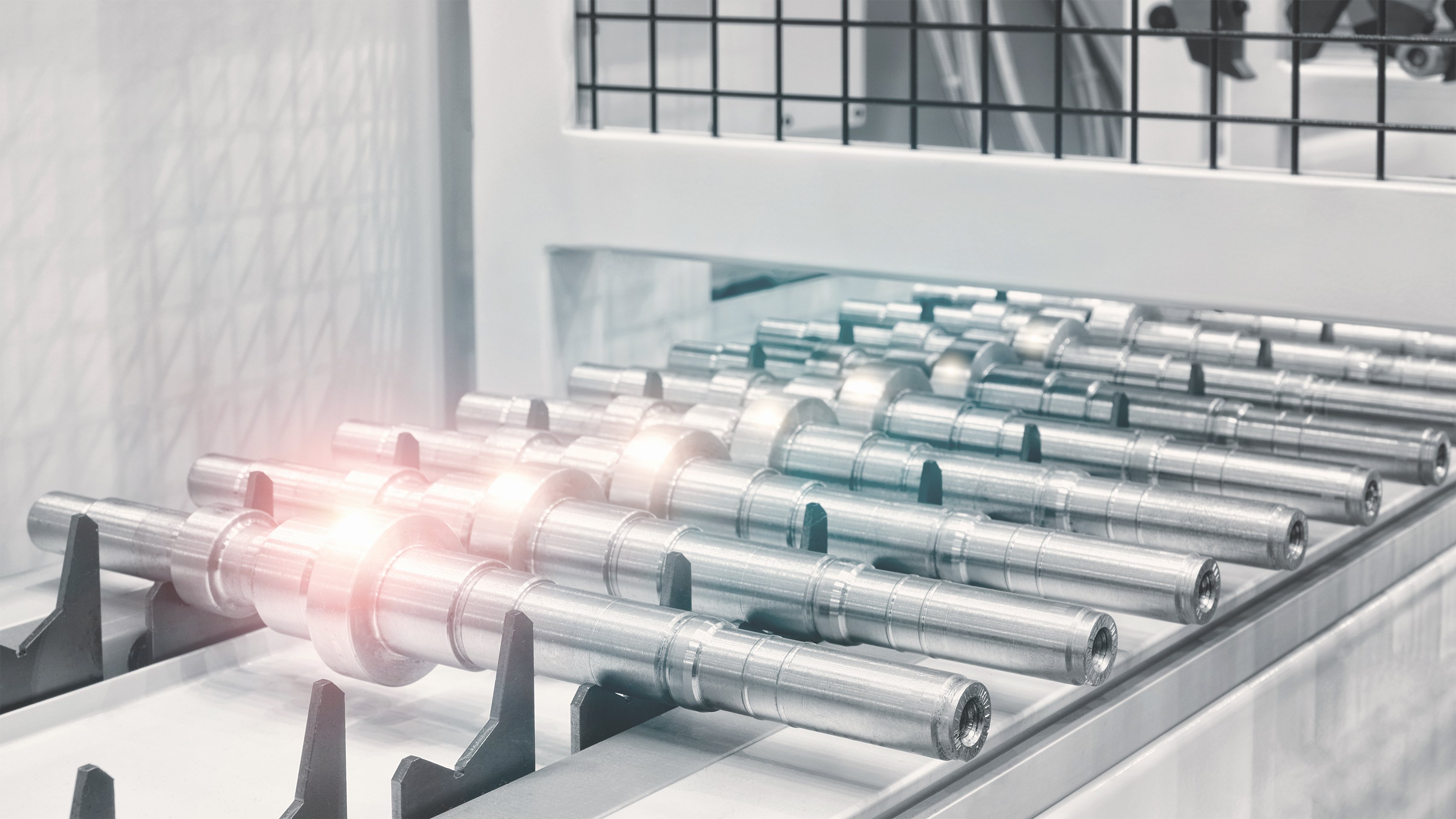

Stepping onto the floor of a rolling mill, pipe plant, or heavy manufacturing facility, you’ll feel it immediately. It is hot, noisy, and unforgiving. Fine metallic dust settles on every surface. Oil mist drifts through the air, coating both machines and controls. Motors and furnaces generate intense heat, while constant vibration rattles equipment from one end of the line to the other.

For operators and quality control teams, this is just another day on the job. But for sensitive testing instruments, it’s a hostile environment. Dust clogs fans. Oil mist creeps into connections. Temperature swings stress electronic boards. Left unprotected, even the most advanced inspection equipment can’t withstand these conditions for long.

The result? Unplanned maintenance, unreliable performance, additional expense, and, in too many cases, premature replacement of high-value systems.

Why Protecting Your Equipment Matters

Inspection equipment, like FOERSTER’s DEFECTOMAT CI/DI , MAGNATEST D, and the STATOGRAPH CM/CM+, is mission critical. Together, these systems ensure product integrity, regulatory compliance, and consistent quality assurance. These CE-compliant systems are ruggedly built to operate in demanding industrial environments, yet even the best-designed instruments benefit from added protection. Pairing them with FOERSTER housing units reduces service interruptions, lowers long-term maintenance costs, and extends equipment life — maximizing reliability and return on investment in the harshest mill and plant conditions.

But when conditions get tough, adding another layer of protection can prevent the costly ripple effect of:

- Downtime: Every hour lost to equipment failure means delayed shipments, idle workers, and mounting production losses.

- Compromised Quality: Without reliable inspection, bad parts risk slipping through, leading to recalls, warranty claims, or customer dissatisfaction.

- Budget Strain: What should be a decade-long investment can become a short-term expense, forcing plants to purchase replacement systems years ahead of schedule.

The cost of leaving equipment unprotected is far greater than the price of preventive protection. Routine service calls and eventual replacement are an expensive cycle that erodes profit margins and undermines reliability. Adding a housing unit is not about making equipment work — it’s about making it work better.

How a Housing Unit Delivers Long-Term Value

FOERSTER understands the demands of our customers and has created a solution to resolve these challenges directly. Combining our equipment with a housing unit provides a protective environment designed to keep inspection systems performing reliably and longer in the harshest mill and plant conditions.

Key features of the 6U housing unit include:

- Positive Air Pressure Protection: A six-fan tray pushes filtered air through the unit, preventing dust and oil mist from entering.

- Temperature Control: A side-mounted cooler/heater maintains stable internal conditions, shielding electronics from temperature fluctuations and operating within OEM specifications for temperature.

- Power Stability: An integrated APC UPS provides surge and power-loss protection, guarding against sudden outages.

- Universal Compatibility: The housing accommodates a variety of instruments, including the DEFECTOMAT CI/DI , MAGNATEST D, and the STATOGRAPH CM/CM+.

- Minimal Maintenance: The only required upkeep is routine filter replacement, which is a fraction of the cost of repeated service calls.

For products like the MAGNATEST TCL, the 4U housing unit offers compact, reliable protection tailored to smaller systems. With dual filtered fans for intake and exhaust, the 4U unit shields instruments and cabling from dust, oil, and dirt while maintaining stable airflow. Operators can control the system externally through a monitor, keyboard, and mouse without ever opening the housing, keeping contaminants out and inspections running smoothly. Designed as a right-sized solution for component applications, the 4U housing extends equipment life, reduces service needs, and delivers peace of mind that critical testing systems will perform reliably shift after shift.

The result is simple but powerful. Instruments last longer, perform more consistently, and deliver the return on investment that plant managers expect. Instead of fighting constant maintenance battles, quality control teams can focus on what matters most — producing reliable, defect-free products.

Actionable Takeaways for Plant and Quality Managers

Protecting your inspection systems is about more than cleanliness; it’s about performance, safety, and profitability. Here’s what you can do today:

- Assess Your Current Setup: Is your testing equipment exposed directly to mill or plant conditions?

- Calculate the True Cost of Downtime: Consider service invoices, production delays, warranty risks, and premature capital spending.

- Invest in Long-Term Protection: Compare the small, predictable cost of housing maintenance to the large, unpredictable cost of repairs and replacement.

- Plan Ahead: If your plant is budgeting for system upgrades or replacements, factor in housing as a critical part of the solution.

The mill floor won’t get any cleaner, cooler, or less demanding. But with FOERSTER’s housing units, your inspection systems don’t have to bear the brunt of it. By investing up front, you extend equipment life, reduce maintenance costs, and safeguard the reliability of your testing operations for years to come.

Share this

You May Also Like

These Related Stories

.jpg)

A Flexible Solution for Long-Product Inspection

Harmonic analysis - 4 points to consider for eddy current testing