The inlet and outlet valves are among the most thermally and mechanically stressed components in an engine. After all, high engine speeds require a fast and precise closing of the valves on the valve seat inserts. Here, high temperatures of 800 - 1000 °C prevail, and even the smallest cracks can lead to valve failure. Furthermore, the valve stem also has to be specially hardened, since it rubs against the cam and is thereby subject to a particularly high load.

.jpg?width=244&height=342&name=Blog6(1).jpg) Figure 1: Valves

Figure 1: Valves

In order to ensure that the material quality meets the requirements of the end customer, FOERSTER offers a fully automated crack and hardness testing system for valves.The proven eddy current test instrument STATOGRAPH is used for crack detection in combination with highly sensitive sensors. It reliably detects longitudinal, transverse and point defects on the valve surface.

Figure 2: STATOGRAPH CM+ with various probes

For hardness testing of the valve stem, a magneto-inductive test method can additionally be used. The required module of the MAGNATEST product family can be easily combined with the STATOGRAPH.

Figure 3: MAGNATEST TCL and encircling coils

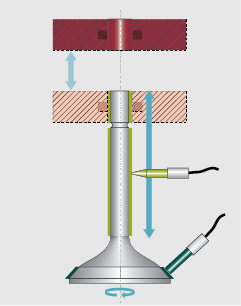

During combined crack detection and hardness testing, the crack detection probes scan the critical parts of the components. For this purpose, the probes can be adjusted to the respective testing area and can either be traversed or can be stationary. For non-destructive inspection of the heat treatment condition, an additional encircling coil is used on the valve stem. (see Figure 4)

Figure 4: Testing principle

Figure 4: Testing principle

We recommend the STATOGRAPH and MAGNATEST test instruments in combinations with the appropriate sensors for the crack detection and structure testing of valves. The comprehensive evaluation and documentation functions enable defect detection at an early stage. With it, product quality is continuously monitored and improved. For further information, please visit our website at: foerstergroup.com