Ball pins, part of the ball joints, are a central component of landing gear. The safety-relevant vehicle component is produced in several production steps from annealed rod wire. In addition to standard components (e.g. according to DIN 71803) customer specific sizes are produced with special geometries. Non-destructive eddy current testing is recommended to determine that the material surface of the ball pins does not include any defects.

Figure 1: Ball pins

Figure 1: Ball pins

The FOERSTER STATOGRAPH eddy current testing instrument monitors the material surface of the ball pins automatically for longitudinal, point and transverse defects. This is done directly in the production line with a performance of approx. 600 parts per hour. For the testing, one or more eddy current probes are used as required.

Figure 2: STATOGRAPH CM+ with various probes

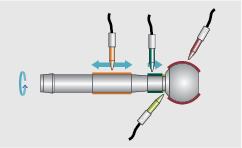

In Figure 3 below, a total of four eddy current probes scan the critical zones of the ball pin and the pressure rod for material defects. This multi-channel version increases the clock rate additionally. The probes used can be adapted individually to the specific geometries of the ball pins. As a result of the customer specific adaption, the error sensitivity can be further increased and reproducible test results can be achieved.

Figure 3: Testing principle

Following the test, automatic sorting takes place in two groups „OK“ and „NOK“. Detailed documentation functions of the testing results support the continuous quality assurance.

We recommend the STATOGRAPH testing system with eddy current probes for surface defect detection (crack testing) of ball pins. This combination enables early detection of surface defects and supports quality assurance. For further information, please visit our website at: foerstergroup.com