Gears play an important role in automotive construction. Without these components, no car could move. In order for the transmission to work well, it is important that the gears are free from defects such as cracks. The non-destructive and automated defect detection by means of eddy current supports the continuous quality assurance of gear components.

To make the crack testing of sintered gear components as efficient as possible FOERSTER has developed a robotic cell for automated testing. Installed in the robot cell is a STATOGRAPH test instrument that carries out the evaluation and documentation of the test signals.

Fig. 2: STATOGRAPH CM+ and flexprobes

To ensure the most sensitive examination of the complex geometric surface of the gears, flexible probes are used. These can be adapted according to the shape of the gear in order to achieve an optimal result.

The robot cell can be integrated into the test process as well as used offline. The components are fed through the test cell via a conveyor belt.

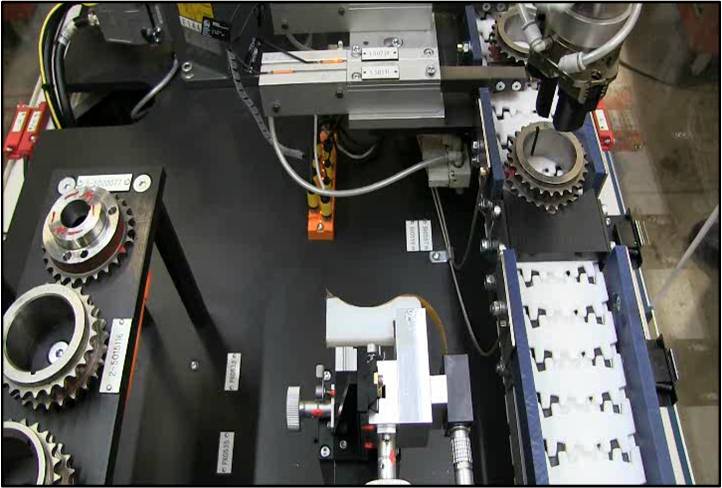

The robot arm picks up the component and rotates it at a defined distance from the flexible probe (see Fig. 3). The test signals are processed immediately and lead to an automatic sorting of the components into good and bad parts. The bad parts are sorted out directly.

Fig. 2: Robotic cell for crack testing of sintered gear

Fig. 2: Robotic cell for crack testing of sintered gear

components

In addition to higher cycle times, the automation also achieves better reproducibility of the testing. As a complete system partner, FOERSTER is in close contact with the customer from planning to commissioning and far beyond, in order to provide an optimal testing solution.

Fig. 3: Look inside the robotic cell

Fig. 3: Look inside the robotic cell

For crack testing of sintered gear components, we recommend the STATOGRAPH test instrument in combination with flexible probes. The probes adapted to the test piece detect defects with high sensitivity. Further information about our products and industry solutions can be found on our website: foerstergroup.com