Components of an injection valve, e.g. the valve housing and the valve sleeve are exposed to very high pressures during operation. In order to withstand these, very high quality demands are placed on the material. Surface defects such as cracks affect loading capacity and can lead to motor damage as well as motor fires. Therefore quality control is necessary during the ongoing process.

For this reason, FOERSTER has developed highly sensitive eddy current probes. With the STATOGRAPH test system, even the finest cracks in these components can be detected. The eddy current method is based on a comparison with reference defects.

Figure 1: STATOGRAPH CM+

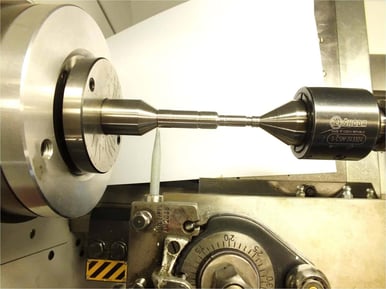

In the following, a reference defect with dimensions of 0.8 mm × 0.1 mm was inserted into a valve housing in three critical areas. Testing is done with a completely automated testing device in the running process. During testing, either the test part is rotated or a rotary head with a rotary probe is used.

Figure 2: Examples for probes and testing of the valve housing

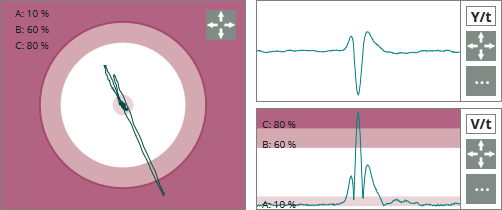

The test result shows that the reference defect is displayed at a test frequency of 1 MHz with a signal level of 100 %, see Fig. 3.

Figure 3: Eddy current display of reference defect

The reference defect is also clearly detected in all three test areas when the surface area is scanned, see Fig. 4.

Figure 4: Scan of the surface with STATOVISION

For crack testing of valve housings and sleeves, we recommend the STATOGRAPH test system in conjunction with an eddy current probe. This combination allows for the detection of even the finest cracks in the material surface and ensures product quality. For further information, please visit: foerstergroup.com