Ball bearings ensure smooth and efficient operation of many machines, motors, gearboxes, and other applications with rotating shafts. A ball bearing is a type of rolling bearing that essentially fulfills three functions:

- It positions the moving shafts.

- It minimizes friction.

- It carries the load.

The ball bearing consists of an inner and outer ring and steel rollers: They are called rolling elements. These rolling bodies are primarily intended to reduce the frictional resistance between the two rings.

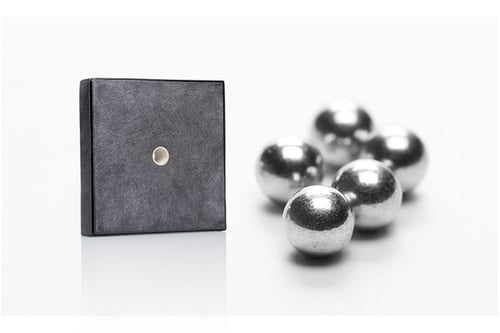

A bearing is composed of several steel balls or rolling elements. If these are damaged or have production-related defects, the entire ball bearing will quickly fail. Therefore, most of the rolling elements are tested. At the same time, it is a great challenge for the manufacturers to control them 100%.

Fig.1: Stainless steel bearings

Most bearings are made out of high-carbon chrome steel. They go through several production steps such as cutting, cold forging, grinding, and heat treatment. On this note, it is imperative that the bearing passes through all production steps correctly. For instance, if a bearing skips the heat treatment process, this can cause immense problems in the entire assembly.

In most production facilities, rolling elements are made of different types of steel. It is impossible to distinguish them visually. However, it is important to find the wrong rolling elements in time, because even a single ball made of a different steel grade can cause a major problem.

Material mix-ups and differences in the hardening process can be detected using eddy currents. The testing devices are able to check the components in milliseconds and enable a 100% inspection during production. The sensitive probes detect changes in electrical conductivity and magnetic permeability. These properties correlate with the material composition and structure. Eddy current testing is therefore an indirect method to check the mechanical properties of a bearing.

The simplest method of testing steel balls is to move them through a comprehensive coil. The testing device automatically detects the ball and forwards the test result to a PLC or directly to a sorting switch. In this way, faulty balls are automatically sorted out. In most cases, the change in electrical conductivity is influenced by a modification of the chemical composition, while a change in magnetic properties is influenced by the difference in hardness.

Fig.2: Steel balls and comprehensive coil

FOERSTER's MAGNATEST TCL, D is recommended for the inspection of such bearings for mixing different materials, hardness condition and grinding cracks.