During the flight, corrosion damage and cracks can occur on turbine blades. The highly sensitive MAGNETOSCOP measuring device can check the turbine blades for corrosion damage caused by high thermal loads. Even the smallest sulfidations are made visible.

Turbine blades in the aviation and energy sectors are subjected to extremely high thermal loads during operation. The optimized nickel-based alloys are adapted to these harsh conditions and withstand extreme operating temperatures.

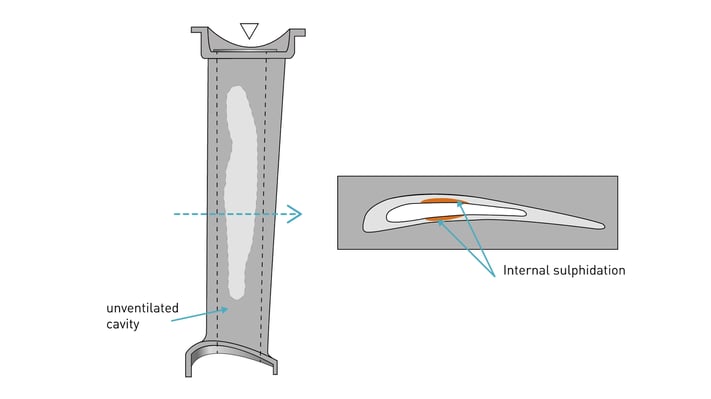

Due to the extreme operating conditions, high-temperature corrosion (sulfidation) can occur despite using high-tech materials. Sulfidation is a chemical process that occurs at temperatures of 700 °C and above. In this process, sulfur (e.g. minute amounts from the kerosene) reacts with the metal of the turbine blade.

Sulfidation is a progressive process that can severely weaken the nickel-based alloy. This damage is not visually detectable and will lead to an invisible threat. Thus, the turbine blades could tear during normal operation. In the worst case, damage the entire turbine.

Fig. 1: Sulfidation on turbine blades

The corrosion of austenitic steel makes the damaged area ferromagnetic. Even a small volume of damage can significantly weaken the material. Therefore, you need highly sensitive measuring equipment to detect sulfidation.

The ferromagnetic material can be detected with a permeability probe. The greater the damage, the stronger the signal for the permeability probe. Thus, the condition of a turbine blade can be evaluated directly via the ferromagnetic content.

Learn more about crack testing. For more information, please click here.

Your permeability measuring devices from FOERSTER

With the mobile permeability measuring device MAGNETOSCOP, even the smallest sulfidations can be made visible during maintenance. If you want to inspect turbine blades in an automated process, the MAGNETOMAT measuring probe can be used as an alternative. To increase the inspection speed in automation, up to four measuring probes can be operated in parallel with the MAGNETOMAT.

If you have any questions or need more information, please feel free to contact our experts. We are glad to help you!