Why are size controls important when installing assemblies?

Size control is an important part of quality assurance in mechanical engineering. They relate to checking the dimensions, tolerances and geometric properties of components and machines. Performing size controls is essential to ensure that components and machines can meet the specified requirements and provide the required performance or function.

Ball bearings are crucial for the optimal functioning of machines and equipment. They help to reduce friction and wear, resulting in a longer service life of machines and equipment. The quality of ball bearings depends, among other things, on the quality of the individual balls. An incorrectly installed ball can cause the entire ball bearing to not work properly and thus affect the performance of the machine.

In pass/fail sorting, the balls are inspected and separated according to their quality. The balls are usually inspected for cracks, irregularities, and other defects using non-destructive testing methods. If several types of balls with different diameters are installed in a machine, it is necessary to measure each individual ball using optical methods and to stop the machine in the event of a deviation. The installation of this measurement method can be expensive and, depending on the application, very time-consuming.

Diameter testing with eddy current

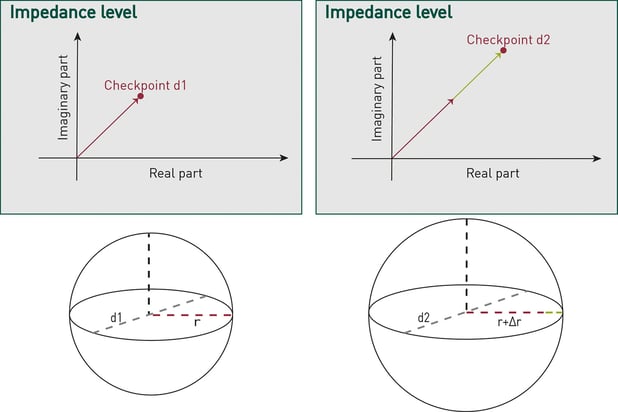

Microstructure testing with eddy current is a non-destructive testing method used to detect changes in the material structure. The method is based on the fact that the magnetic behavior of materials depends on their chemical composition and thus on conductivity and magnetic permeability. If, for example, balls with the same material and machining properties are tested, no differences in the eddy current signals can be detected. However, as the ball diameters vary, the mass to be tested within the test coil changes and the total inductive resistance becomes greater or less. An example of this is shown in the illustration below. This effect can enable components to be sorted according to geometric features by setting adjusted threshold values at the same time.

Automatic test triggering with MAGNATEST TCL

In production lines, components are usually brought to the actual assembly site in large quantities via feeders. Frequently, the components are also separated to be able to feed the balls in a targeted manner, in the example of a bearing. With the help of the automatic test triggering of the MAGNATEST TCL, coil and probe solutions can be integrated directly into these feed lines and the time-consuming external test triggering of a controller is no longer necessary. For setting the automated test trigger, a practical setting assistant is available in the MAGNATEST TCL software.

Define threshold with the setting assistant

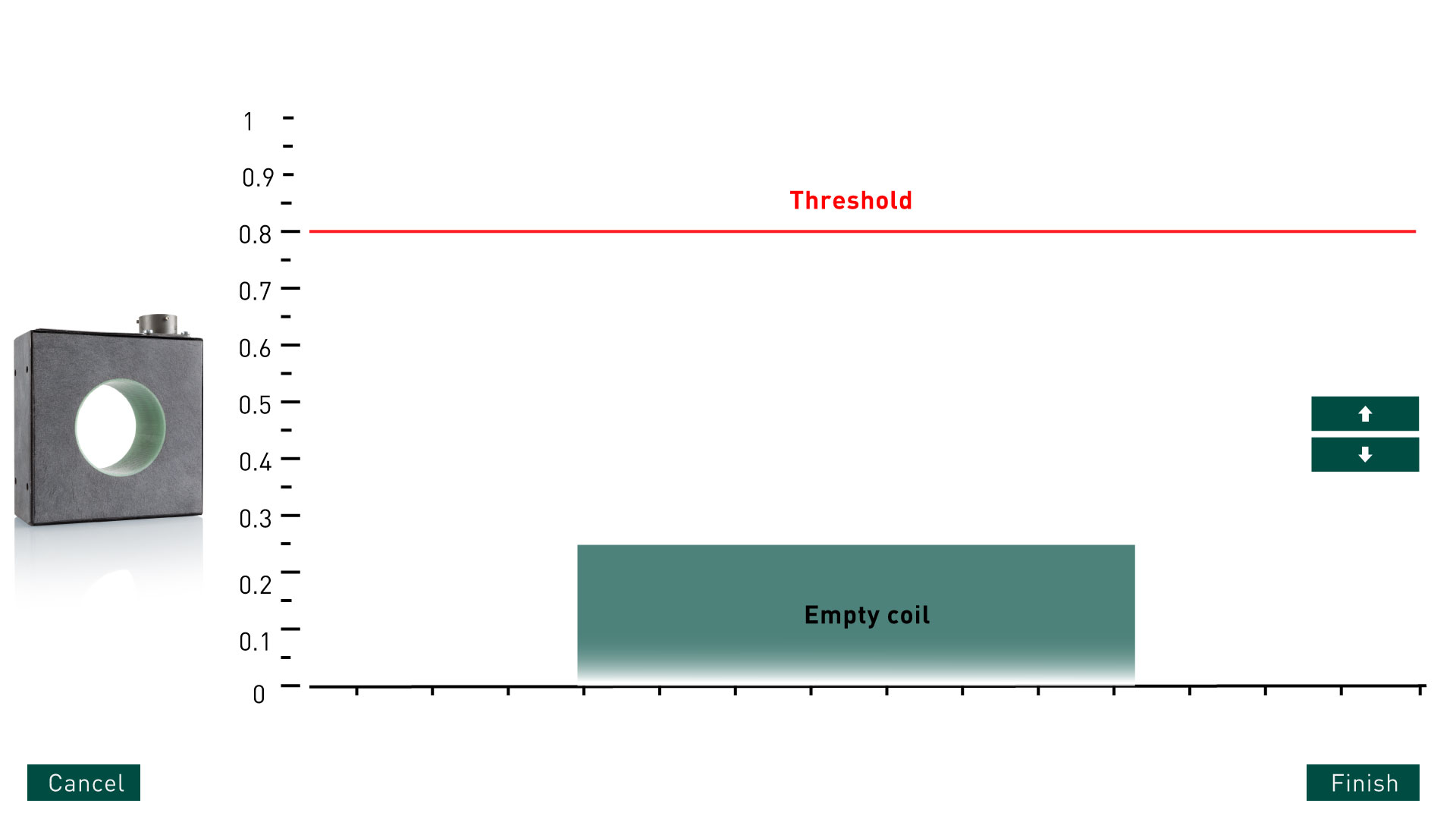

Below is the auto trigger settings page as seen on the software screen. The following 3 easy steps have to be done to define the threshold:

- Move one or more test parts through the coil or past the probe. The green bar will show the signal generated by the component.

- The threshold can be increased or decreased with the arrows.

- Click "Finish" to complete the auto trigger settings.

Sorting of components according to geometric properties

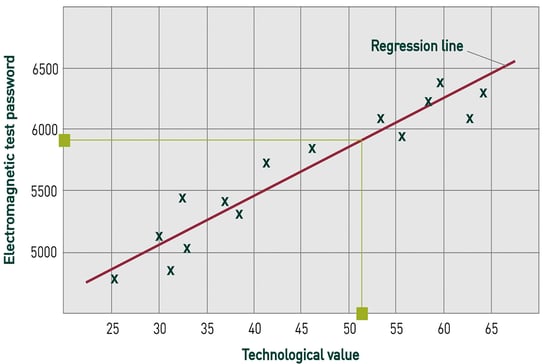

If a simple pass/fail sorting of the components is not sufficient, the MAGNATEST D offers another possibility for a more precise specification of the tested properties. For example, this test instrument can be used to create separate classes to distinguish the components and later to carry out sorting using the control of a mechanism. If a linear behavior of the investigated properties is detected, the MAGNATEST D can also be equipped with an additional tool. The MAGNA CLARIS software feature combines technologically measured values with the characteristic values of electromagnetic testing. Below is the graph that illustrates this sorting process.

Take the opportunity and tell us your requirements to secure your production processes!

Our team offers comprehensive feasibility studies to analyze your requirements and present you with a solution for the testing task. Contact us now and start your successful cooperation with us.